Stainless Steel is a steel alloy containing chromium, well known for its corrosion resistance where durability and cleanliness are important. Here at Metals4U-Online, we only sell the highest quality stainless metals, and we ship direct to you! No order is cut 2 small! We’re HUGE!

Type 304 stainless steel (angle, etc) is a steel alloy containing chromium (18 to 20%)...

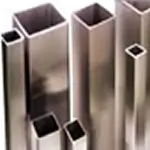

T-304 Stainless Steel Square Tube and Rectangular Tubing is produced by rolling the proper size...

Stainless Steel Flat bar is a steel alloy containing chromium, widely used in applications where...

Stainless Steel – a steel alloy containing chromium, well known for its corrosion resistance where...

A stainless-steel square bar is a steel bar with a square cross-section that’s made from...

Stainless steel T-304 is a chromium-nickel alloy sheet that is known for its strength, durability, and...

Type 304 Stainless Steel Sheet and Plate is a steel alloy containing chromium. T-304 sheet...

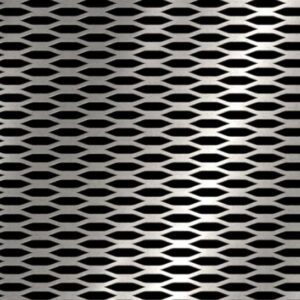

Stainless steel expanded metal is manufactured by slitting and stretching stainless steel sheets, producing diamond-shaped...

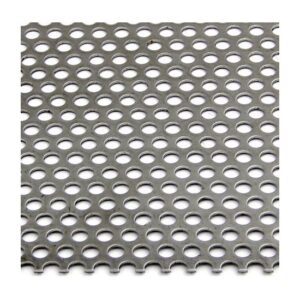

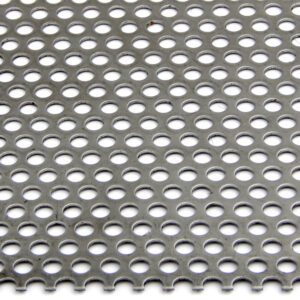

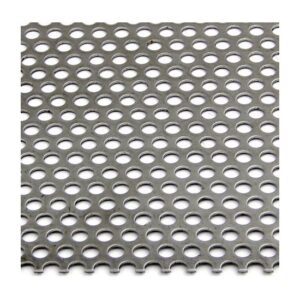

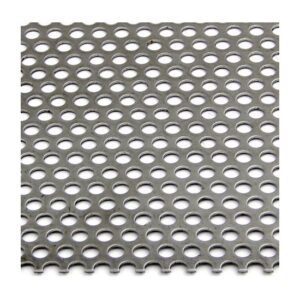

A stainless steel perforated sheet is a sheet of stainless steel that has been punched,...

Stainless Steel Pipe is a steel alloy containing chromium, widely used in applications where corrosion...

Stainless Steel Round Tube is the preferred choice where corrosion-resistance, durability, and sanitation are important...

Stainless steel all thread, also known as a stainless steel threaded rod, is a long,...

Metals4Uonline offers various options. Whether you need Dividers, J-Caps, Inside Corners, Outside Corners, or much more,...

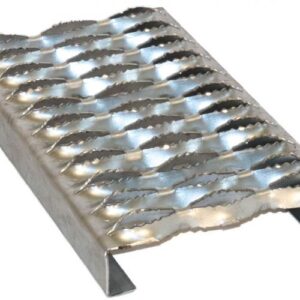

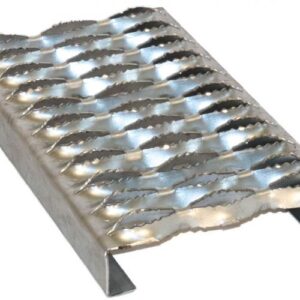

Plank grating is a type of safety grating used in various settings to provide secure...

Our Stainless Steel Economy Value Packs are pre-packaged in 4ft lengths. Great for building up...

SSSQ414

SHOP THIS ITEM $8.85 – $16.61 Select options This product has multiple variants. The options may be chosen on the product page

SSSQ516

SHOP THIS ITEM $13.37 – $30.05 Select options This product has multiple variants. The options may be chosen on the product page

SSSQ438

SHOP THIS ITEM $10.83 – $28.34 Select options This product has multiple variants. The options may be chosen on the product page

SSSQ412

SHOP THIS ITEM $13.33 – $43.96 Select options This product has multiple variants. The options may be chosen on the product page

SSSQ458

SHOP THIS ITEM $13.55 – $52.22 Select options This product has multiple variants. The options may be chosen on the product page

SSSQ434

SHOP THIS ITEM $20.99 – $89.89 Select options This product has multiple variants. The options may be chosen on the product page

SSSQ478

SHOP THIS ITEM $42.55 – $196.30 Select options This product has multiple variants. The options may be chosen on the product page

SSSQ41

SHOP THIS ITEM $27.82 – $135.36 Select options This product has multiple variants. The options may be chosen on the product page

SSSQ4114

SHOP THIS ITEM $44.85 – $233.64 Select options This product has multiple variants. The options may be chosen on the product page

SSSQ4112

SHOP THIS ITEM $59.90 – $324.83 Select options This product has multiple variants. The options may be chosen on the product page

SSSQ4134

SHOP THIS ITEM $82.23 – $457.35 Select options This product has multiple variants. The options may be chosen on the product page

SSSQ42

SHOP THIS ITEM $108.10 – $611.68 Select options This product has multiple variants. The options may be chosen on the product page

SSSQ4212

SHOP THIS ITEM $260.00 – $1,385.00 Select options This product has multiple variants. The options may be chosen on the product page

SSFXM1216

SHOP THIS ITEM $40.00 – $111.00 Select options This product has multiple variants. The options may be chosen on the product page

SSPE41618316F

SHOP THIS ITEM $96.24 – $268.72 Select options This product has multiple variants. The options may be chosen on the product page

SSPE41631638

SHOP THIS ITEM $130.00 – $390.00 Select options This product has multiple variants. The options may be chosen on the product page

SSPE4161438

SHOP THIS ITEM $95.12 – $265.36 Select options This product has multiple variants. The options may be chosen on the product page

SSPI41440

SHOP THIS ITEM $13.00 – $25.00 Select options This product has multiple variants. The options may be chosen on the product page

(0.675 od x 0.091 wall x 0.493 id)*

SSPI43840

SHOP THIS ITEM $7.70 – $46.20 Select options This product has multiple variants. The options may be chosen on the product page

(0.840 od x 0.109 wall x 0.622 id)*

SSPI41240

SHOP THIS ITEM $6.05 – $36.30 Select options This product has multiple variants. The options may be chosen on the product page

(1.050 od x 0.113 wall x 0.824 id)*

SSPI43440

SHOP THIS ITEM $7.92 – $47.52 Select options This product has multiple variants. The options may be chosen on the product page

(1.315 od x 0.133 wall x 1.049 id)*

SSPI4140

SHOP THIS ITEM $11.44 – $68.64 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)

SSSH4244PVC

SHOP THIS ITEM $16.56 – $88.72 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)

SSSH4224PVC

SHOP THIS ITEM $14.03 – $58.38 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)

SSSH4204PVC

SHOP THIS ITEM $16.00 – $82.00 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)

SSSH4184PVC

SHOP THIS ITEM $18.40 – $110.80 Select options This product has multiple variants. The options may be chosen on the product page

SSAT41420

SHOP THIS ITEM $8.00 – $13.00 Select options This product has multiple variants. The options may be chosen on the product page

SSAT451618

SHOP THIS ITEM $8.80 – $14.60 Select options This product has multiple variants. The options may be chosen on the product page

SSAT43816

SHOP THIS ITEM $14.20 – $23.15 Select options This product has multiple variants. The options may be chosen on the product page

SSAT658

SHOP THIS ITEM $26.33 – $49.67 Select options This product has multiple variants. The options may be chosen on the product page

SSAT41213

SHOP THIS ITEM $18.00 – $33.00 Select options This product has multiple variants. The options may be chosen on the product page

SSAT45811

SHOP THIS ITEM $27.93 – $52.87 Select options This product has multiple variants. The options may be chosen on the product page

SSAT63410

SHOP THIS ITEM $73.53 – $144.07 Select options This product has multiple variants. The options may be chosen on the product page

SSAT4LH5/8-11

SHOP THIS ITEM $13.95 – $28.91 Select options This product has multiple variants. The options may be chosen on the product page

SSAT43410

SHOP THIS ITEM $37.53 – $72.07 Select options This product has multiple variants. The options may be chosen on the product page

SSAT41LH

SHOP THIS ITEM $65.00 – $96.00 Select options This product has multiple variants. The options may be chosen on the product page

SSAT41147

SHOP THIS ITEM $105.64 – $207.67 Select options This product has multiple variants. The options may be chosen on the product page

SSAT41126

SHOP THIS ITEM $129.00 – $255.00 Select options This product has multiple variants. The options may be chosen on the product page

SAN411211222I

SHOP THIS ITEM $24.24 Add to cart

SSAN411211222

SHOP THIS ITEM $24.24 Add to cart

SSFL4CAP

SHOP THIS ITEM $25.59 Add to cart

SSFL4FLDIVIVDER

SHOP THIS ITEM $24.10 Add to cart

SSPG4.75

SHOP THIS ITEM $199.41 – $388.81 Select options This product has multiple variants. The options may be chosen on the product page

SSPG167

SHOP THIS ITEM $190.18 – $370.36 Select options This product has multiple variants. The options may be chosen on the product page

SSPG11.75

SHOP THIS ITEM $271.44 – $445.73 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)

SSSH4164PVC

SHOP THIS ITEM $20.50 – $136.00 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)

SSSH4144PVC

SHOP THIS ITEM $22.50 – $160.00 Select options This product has multiple variants. The options may be chosen on the product page

PVC (Coated)

SSSH411

SHOP THIS ITEM $33.00 – $254.00 Select options This product has multiple variants. The options may be chosen on the product page

SSPE41638916

SHOP THIS ITEM $94.00 – $262.00 Select options This product has multiple variants. The options may be chosen on the product page

SSPE41431614

SHOP THIS ITEM $110.00 – $335.00 Select options This product has multiple variants. The options may be chosen on the product page

3/4" x 3/4" x 16ga.(.063") Stainless Steel Square Tube T-304 Mill Finish (...

SSST4343416MF

SHOP THIS ITEM $4.40 – $26.40 Select options This product has multiple variants. The options may be chosen on the product page

1" x 1" x 16ga.(.063") Stainless Steel Square Tube T-304 Mill Finish (...

SSST41116MF

SHOP THIS ITEM $4.60 – $27.59 Select options This product has multiple variants. The options may be chosen on the product page

3/4" x 3/4" x 16ga.(.063") Stainless Steel Square Tube T-304 180 Polished Finish

SSST4343416180P

SHOP THIS ITEM $7.81 – $46.86 Select options This product has multiple variants. The options may be chosen on the product page

1" x 1" x 11ga.(.120")Stainless Steel Square Tube T-304 Mill Finish (...

SSST41111MF

SHOP THIS ITEM $7.04 – $42.24 Select options This product has multiple variants. The options may be chosen on the product page

1" x 1" x 16ga.(.063") Stainless Steel Square Tube T-304 180 Polished Finish

SSST41116180P

SHOP THIS ITEM $4.95 – $29.70 Select options This product has multiple variants. The options may be chosen on the product page

180 Polished Stainless Steel Square Tube

SSST41111180P

SHOP THIS ITEM $7.59 – $45.54 Select options This product has multiple variants. The options may be chosen on the product page

1-1/4" x 1-1/4" x 16ga.(.063") Stainless Steel Square Tube T-304 ...

SSST411411416MF

SHOP THIS ITEM $9.48 – $56.89 Select options This product has multiple variants. The options may be chosen on the product page

1-1/4" x 1-1/4" x 16ga.(.063") Stainless Steel Square Tube T-304 180 ...

SSST411411416180P

SHOP THIS ITEM $12.22 – $73.32 Select options This product has multiple variants. The options may be chosen on the product page

1-1/4" x 1-1/4" x 11ga.(.120') Stainless Steel Square Tube ...

SSST411411411MF

SHOP THIS ITEM $16.94 – $101.64 Select options This product has multiple variants. The options may be chosen on the product page

1-1/4" x 1-1/4" x 11ga.(.120") Stainless Steel Square Tube T-304 180 ...

SSST411411411180P

SHOP THIS ITEM $12.54 – $75.24 Select options This product has multiple variants. The options may be chosen on the product page

1-1/2" x 1-1/2" x 16ga.(.063") Stainless Steel Square Tube T-304 180 ...

SSST411211216180P

SHOP THIS ITEM $14.30 – $85.80 Select options This product has multiple variants. The options may be chosen on the product page

1-1/2" x 1-1/2" x 16ga.(.063") Stainless Steel Square Tube T-304 ...

SSST411211216MF

SHOP THIS ITEM $15.40 – $92.40 Select options This product has multiple variants. The options may be chosen on the product page

1-1/2" x 1-1/2" x 11ga.(.120") Stainless Steel Square Tube T-304 180 ...

SSST411211211180P

SHOP THIS ITEM $17.34 – $104.02 Select options This product has multiple variants. The options may be chosen on the product page

1-1/2" x 1-1/2" x 11ga.(.120") Stainless Steel Square Tube T-304 ...

SSST411211211MF

SHOP THIS ITEM $13.20 – $79.20 Select options This product has multiple variants. The options may be chosen on the product page

1" x 2" x 16ga.(.063") Stainless Steel Rectangular Tube T-304 Mill Finish (...

SSST41216MF

SHOP THIS ITEM $7.70 – $46.20 Select options This product has multiple variants. The options may be chosen on the product page

1" x 2" x 16ga.(.063") Stainless Steel Rectangular Tube T-304 180 Polished Finish

SSST41216180P

SHOP THIS ITEM $12.68 – $76.08 Select options This product has multiple variants. The options may be chosen on the product page

1" x 2" x 11ga.(.120") Stainless Steel Rectangular Tube T-304 Mill Finish (...

SSST41211MF

SHOP THIS ITEM $13.75 – $82.50 Select options This product has multiple variants. The options may be chosen on the product page

2" x 2" x 16ga.(.063") Stainless Steel Square Tube T-304 Mill Finish (...

SSST42216MF

SHOP THIS ITEM $8.58 – $51.48 Select options This product has multiple variants. The options may be chosen on the product page

1" x 2" x 11ga.(.120") Stainless Steel Rectangular Tube T-304 180 Polished Finish

SSST41211180P

SHOP THIS ITEM $22.30 – $133.80 Select options This product has multiple variants. The options may be chosen on the product page

2" x 2" x 11ga.(.120") Stainless Steel Square Tube T-304 Mill Finish (...

SSST42211MF

SHOP THIS ITEM $15.09 – $90.55 Select options This product has multiple variants. The options may be chosen on the product page

2" x 2" x 16ga.(.063") Stainless Steel Square Tube T-304 180 Polished Finish

SSST42216180P

SHOP THIS ITEM $8.95 – $53.72 Select options This product has multiple variants. The options may be chosen on the product page

2" x 2" x 11ga.(.120") Stainless Steel Square Tube T-304 180 Polished Finish

SSST42211180P

SHOP THIS ITEM $17.05 – $102.30 Select options This product has multiple variants. The options may be chosen on the product page

SSRT6S375035

SHOP THIS ITEM $7.04 – $42.24 Select options This product has multiple variants. The options may be chosen on the product page

SSRT6S500065

SHOP THIS ITEM $13.75 – $82.50 Select options This product has multiple variants. The options may be chosen on the product page

SSRT6S750065

SHOP THIS ITEM $17.60 – $105.60 Select options This product has multiple variants. The options may be chosen on the product page

SSRT6S1000065

SHOP THIS ITEM $21.23 – $127.38 Select options This product has multiple variants. The options may be chosen on the product page

SSRT6S1250065

SHOP THIS ITEM $33.77 – $202.62 Select options This product has multiple variants. The options may be chosen on the product page

SSRT4W250035

SHOP THIS ITEM $4.40 – $26.40 Select options This product has multiple variants. The options may be chosen on the product page

SSRT4w375035

SHOP THIS ITEM $4.18 – $25.08 Select options This product has multiple variants. The options may be chosen on the product page

SSRT4W500035

SHOP THIS ITEM $5.50 – $33.00 Select options This product has multiple variants. The options may be chosen on the product page

SSRT4W625035

SHOP THIS ITEM $7.70 – $46.20 Select options This product has multiple variants. The options may be chosen on the product page

SSPE41438916

SHOP THIS ITEM $110.16 – $310.48 Select options This product has multiple variants. The options may be chosen on the product page

SSPE4111438

SHOP THIS ITEM $180.48 – $521.44 Select options This product has multiple variants. The options may be chosen on the product page

SSPE411121116

SHOP THIS ITEM $135.00 – $415.00 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)

SSSH42B16

SHOP THIS ITEM $24.00 – $135.00 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)

SSSH42B14

SHOP THIS ITEM $26.00 – $159.00 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)

SSSH42B11

SHOP THIS ITEM $33.00 – $244.00 Select options This product has multiple variants. The options may be chosen on the product page

3/16" Stainless Steel Round T-316

SSRO6316

SHOP THIS ITEM $5.00 – $8.50 Select options This product has multiple variants. The options may be chosen on the product page

SSRO418

SHOP THIS ITEM $5.93 – $18.00 Select options This product has multiple variants. The options may be chosen on the product page

SSRO3316

SHOP THIS ITEM $5.00 – $19.60 Select options This product has multiple variants. The options may be chosen on the product page

SSRO4316

SHOP THIS ITEM $11.89 – $67.28 Select options This product has multiple variants. The options may be chosen on the product page

SSRO314

SHOP THIS ITEM $5.00 – $40.00 Select options This product has multiple variants. The options may be chosen on the product page

SSRO414

SHOP THIS ITEM $2.12 – $22.84 Select options This product has multiple variants. The options may be chosen on the product page

SSRO614

SHOP THIS ITEM $5.00 – $21.00 Select options This product has multiple variants. The options may be chosen on the product page

SSRO3516

SHOP THIS ITEM $2.61 – $18.29 Select options This product has multiple variants. The options may be chosen on the product pageStainless Steel, is also described as inox steel (derived from French: “inoxydable” meaning stainless), is a steel alloy. The major difference between stainless steel and ordinary (carbon) steel is that the former does not undergo corrosion when exposed to water or air while the latter does. Therefore, stainless steel finds use in applications that not only need the properties of steel but also require high resistance to corrosion.

During the steel making process, various elements are added to ordinary steel when it is still in its molten state. The elements added, as well as the quantities of those elements, will change the properties of steel. If, during the process of steel production, the amount of chromium added exceeds 10.5% of the total mass of the alloy, the resultant steel alloy is stainless steel.

Stainless Steel is highly resistant to corrosion because of the large amount of chromium that it contains. This chromium reacts with the oxygen present in the atmosphere to form a passive layer of chromium oxide. As a result of the formation of this layer, oxygen in the atmosphere is unable to reach the actual steel surface; this protects the metal alloy from rusting or corroding. However, for this to happen, not only should sufficient amount of chromium be present, so should sufficient amount of oxygen. Therefore, in environments having low oxygen levels, stainless steel might still undergo corrosion.

The property of non-corrosion of an alloy of iron and chromium was first discovered by Pierre Berthier, who was a French metallurgist, in the year 1821. However, in the 19th century, metallurgists were not able to actually produce a steel alloy that had high levels of chromium and low levels of carbon. The alloys that they produced had high levels of carbon and were too brittle. It wasn’t until the latter part of the 19th century and earlier part of the 20th century, however, that a number of researchers, like the Frenchman Leon Guillet and others in Europe and the United States of America, managed to create alloys which, today, we would consider as stainless steel. And all of this started when a German chemist called Hans Goldschmidt developed a thermite process to produce chromium that was carbon-free. By the third decade of the twentieth century, mass production of stainless steel had set in.

* Prices subject to change without notice due to the Metals Market fluctuations.

* All ‘value length’ and ‘value pack’ item measurements are subject to a “mill tolerance”. A product may be produced several thousandths of an inch, either over or under the stated thickness, and still be within “mill tolerance”. This does NOT apply to Cut To Size items. Those will be +.125″, -0.00″ tolerances.

CALIFORNIA PROPOSITION 65

This product can expose you to chemicals which are known to the State of California to cause cancer, birth defects or other reproductive harm. For more information, go to www.P65Warnings.ca.gov

Prices subject to change without notice due to the Metals Market fluctuations. | All ‘value length’ and ‘value pack’ item measurements are subject to a “mill tolerance”. | A product may be produced several thousandths of an inch, either over or under the stated thickness, and still be within “mill tolerance”. This does NOT apply to Cut To Size items. Those will be +.125”, -0.00” tolerances.

|

Pipe Size* |

O.D.

(in.) |

Schedule (10, 40, 80)

Wall Thickness (in.)** |

|||||

|---|---|---|---|---|---|---|---|

| Sch.10 | Sch.40 | Sch.80 | |||||

| Wall (in) | I.D. (in) | Wall (in) | I.D. (in) | Wall (in) | I.D. (in) | ||

| 1/8" | 0.41 od | 0.049 in | 0.312 id | 0.07 in | 0.269 id | ||

|

Weight (lbs/ft.) |

Steel | 0.183 lbs/ft | 0.247 lbs/ft | ||||

| Stainless | |||||||

| Aluminum | |||||||

| 1/4" | 0.54 od | 0.065 in | 0.410 id | 0.090 in | 0.364 id | 0.119 in | 0.302 id |

|

Weight (lbs/ft.) |

Steel | 0.333 lbs/ft | 0.429 lbs/ft | 0.535 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.147 lbs/ft | ||||||

| 3/8" | 0.675 od | 0.065 in | 0.545 id | 0.091 in | 0.493 id | 0.126 in | 0.423 id |

|

Weight (lbs/ft.) |

Steel | 0.420 lbs/ft | 0.570 lbs/ft | 0.740 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.196 lbs/ft | ||||||

| 1/2" | 0.840 od | 0.083 in | 0.674 id | 0.109 in | 0.622 id | 0.147 in | 0.546 id |

|

Weight (lbs/ft.) |

Steel | 0.670 lbs/ft | 0.850 lbs/ft | 1.090 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.294 lbs/ft | 0.384 lbs/ft | |||||

| 3/4" | 1.050 od | 0.083 in | 0.884 id | 0.113 in | 0.824 id | 0.154 in | 0.742 id |

|

Weight (lbs/ft.) |

Steel | 0.86 lbs/ft | 1.13 lbs/ft | 1.48 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.391 | 0.520 | |||||

| 1" | 1.315 od | 0.109 in | 1.097 id | 0.133 in | 1.049 id | 0.179 in | 0.957 id |

|

Weight (lbs/ft.) |

Steel | 1.41 lbs/ft | 1.68 lbs/ft | 2.17 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.481 lbs/ft | 0.581 lbs/ft | 0.781 lbs/ft | ||||

| 1-1/4" | 1.66 od | 0.109 in | 1.442 id | 0.140 in | 1.380 id | 0.191 in | 1.278 id |

|

Weight (lbs/ft.) |

Steel | 1.81 lbs/ft | 2.27 lbs/ft | 3.00 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.618 lbs/ft | 0.785 lbs/ft | 1.040 lbs/ft | ||||

| 1-1/2" | 1.90 od | 0.109 in | 1.682 id | 0.145 in | 1.610 id | 0.200 in | 1.500 id |

|

Weight (lbs/ft.) |

Steel | 2.09 lbs/ft | 2.72 lbs/ft | 3.63 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.714 lbs/ft | 0.939 lbs/ft | 1.260 lbs/ft | ||||

| 2" | 2.375 od | 0.109 in | 2.157 id | 0.154 in | 2.067 id | 0.218 in | 1.939 id |

|

Weight (lbs/ft.) |

Steel | 2.64 lbs/ft | 3.66 lbs/ft | 5.03 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.903 lbs/ft | 1.260 lbs/ft | 1.740 lbs/ft | ||||

| 2-1/2" | 2.875 od | 0.120 in | 2.635 id | 0.203 in | 2.469 id | 0.276 in | 2.323 id |

|

Weight (lbs/ft.) |

Steel | 3.53 lbs/ft | 5.80 lbs/ft | 7.67 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 1.209 lbs/ft | 2.000 lbs/ft | |||||

| 3" | 3.50 od | 0.120 in | 3.26 id | 0.216 in | 3.068 id | 0.30 in | 2.90 id |

|

Weight (lbs/ft.) |

Steel | 4.34 lbs/ft | 7.58 lbs/ft | 10.26 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 1.483 lbs/ft | 2.620 lbs/ft | 3.55 lbs/ft | ||||

| 3-1/2" | 4.00 od | 0.120 in | 3.76 id | 0.226 in | 3.550 id | 0.318 in | 3.360 id |

|

Weight (lbs/ft.) |

Steel | 4.98 lbs/ft | 9.12 lbs/ft | 12.52 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 3.150 lbs/ft | 4.33 lbs/ft | |||||

| 4" | 4.50 od | 0.120 in | 4.26 id | 0.237 in | 4.026 id | 0.337 in | 3.826 id |

|

Weight (lbs/ft.) |

Steel | 5.62 lbs/ft | 10.80 lbs/ft | 15.00 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 1.922 lbs/ft | 3.730 lbs/ft | 5.180 lbs/ft | ||||

| 5" | 5.563 od | 0.134 in | 5.295 id | 0.258 in | 5.047 id | 0.375 in | 4.813 id |

|

Weight (lbs/ft.) |

Steel | 7.78 lbs/ft | 14.63 lbs/ft | 20.80 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 2.660 lbs/ft | 5.050 lbs/ft | 7.190 lbs/ft | ||||

| 6" | 6.625 od | 0.134 in | 6.357 id | 0.280 in | 6.065 id | 0.432 in | 5.761 id |

|

Weight (lbs/ft.) |

Steel | 9.30 lbs/ft | 18.99 lbs/ft | 28.60 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 3.181 lbs/ft | 6.560 lbs/ft | 9.880 lbs/ft | ||||

| 8" | 8.625 od | 0.148 in | 8.329 id | 0.322 in | 7.981 id | 0.500 in | 7.625 id |

|

Weight (lbs/ft.) |

Steel | 13.41 lbs/ft | 28.58 lbs/ft | 43.43 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 9.88 lbs/ft | 15.010 lbs/ft | |||||

|

*Nominal sizes apply - Pipe Size is the generic Industry Size Standard for reference only **Tolerances may vary slightly from each manufacturer |

|||||||

| Ga# | Sheet Steel | Galvanized Steel | Stainless Steel | Aluminum | Strip & Tubing | ||||

|---|---|---|---|---|---|---|---|---|---|

|

Ga (in.) |

Wgt (lb/ft2) |

Ga (in.) |

Wgt (lb/ft2) |

Ga (in.) |

Wgt (lb/ft2) |

Ga (in.) |

Wgt (lb/ft2) |

Ga (in.) |

|

| 38 | 0.0060 | 0.0062 | 0.0040 | ||||||

| 37 | 0.0064 | 0.0066 | 0.0045 | ||||||

| 36 | 0.0067 | 0.0070 | 0.0050 | 0.004 | |||||

| 35 | 0.0075 | 0.0078 | 0.0056 | 0.005 | |||||

| 34 | 0.0082 | 0.0086 | 0.0063 | 0.007 | |||||

| 33 | 0.0090 | 0.0094 | 0.0071 | 0.008 | |||||

| 32 | 0.0097 | 0.0102 | 0.0080 | 0.009 | |||||

| 31 | 0.0105 | 0.0109 | 0.0089 | 0.010 | |||||

| 30 | 0.0120 | 0.500 | 0.016 | 0.656 | 0.0125 | 0.0100 | 0.141 | 0.012 | |

| 29 | 0.0135 | 0.563 | 0.017 | 0.719 | 0.0141 | 0.0113 | 0.160 | 0.013 | |

| 28 | 0.0149 | 0.625 | 0.019 | 0.781 | 0.0156 | 0.0126 | 0.178 | 0.014 | |

| 27 | 0.0164 | 0.688 | 0.020 | 0.844 | 0.0172 | 0.0142 | 0.200 | 0.016 | |

| 26 | 0.0179 | 0.750 | 0.022 | 0.906 | 0.0187 | 0.756 | 0.0159 | 0.224 | 0.018 |

| 25 | 0.0209 | 0.875 | 0.025 | 1.031 | 0.0219 | 0.0179 | 0.253 | 0.020 | |

| 24 | 0.0239 | 1.000 | 0.028 | 1.156 | 0.0250 | 1.008 | 0.0201 | 0.284 | 0.022 |

| 23 | 0.0269 | 1.125 | 0.031 | 1.281 | 0.0281 | 0.0226 | 0.319 | 0.025 | |

| 22 | 0.0299 | 1.250 | 0.034 | 1.406 | 0.0312 | 1.26 | 0.0253 | 0.357 | 0.028 |

| 21 | 0.0329 | 1.375 | 0.037 | 1.531 | 0.0344 | 0.0285 | 0.402 | 0.032 | |

| 20 | 0.0359 | 1.500 | 0.040 | 1.656 | 0.0375 | 1.512 | 0.0320 | 0.452 | 0.035 |

| 19 | 0.0418 | 1.750 | 0.046 | 1.906 | 0.0437 | 0.0359 | 0.507 | 0.042 | |

| 18 | 0.0478 | 2.000 | 0.052 | 2.156 | 0.0500 | 2.016 | 0.0403 | 0.569 | 0.049 |

| 17 | 0.0538 | 2.250 | 0.058 | 2.406 | 0.0562 | 0.0453 | 0.639 | 0.058 | |

| 16 | 0.0598 | 2.500 | 0.064 | 2.656 | 0.0625 | 2.52 | 0.0508 | 0.717 | 0.065 |

| 15 | 0.0673 | 2.813 | 0.071 | 2.969 | 0.0703 | 0.0571 | 0.806 | 0.072 | |

| 14 | 0.0747 | 3.125 | 0.079 | 3.281 | 0.0781 | 3.15 | 0.0641 | 0.905 | 0.083 |

| 13 | 0.0897 | 3.750 | 0.093 | 3.906 | 0.0937 | 0.0720 | 1.016 | 0.095 | |

| 12 | 0.1046 | 4.375 | 0.108 | 4.531 | 0.1094 | 4.41 | 0.0808 | 1.140 | 0.109 |

| 11 | 0.1196 | 5.000 | 0.123 | 5.156 | 0.1250 | 5.04 | 0.0907 | 1.280 | 0.120 |

| 10 | 0.1345 | 5.625 | 0.138 | 5.781 | 0.1406 | 5.67 | 0.1019 | 1.438 | 0.134 |

| 9 | 0.1495 | 6.250 | 0.153 | 6.406 | 0.1562 | 0.1144 | 1.614 | 0.148 | |

| 8 | 0.1644 | 6.875 | 0.168 | 7.031 | 0.1719 | 6.93 | 0.1285 | 1.813 | 0.165 |

| 7 | 0.1793 | 7.500 | 0.1875 | 7.871 | 0.1443 | 2.036 | 0.180 | ||

| 6 | 0.1943 | 8.125 | 0.2031 | 0.1620 | 2.286 | 0.203 | |||

| 5 | 0.2092 | 8.750 | 0.2187 | 0.1819 | 0.220 | ||||

| 4 | 0.2242 | 9.375 | 0.2344 | 0.2043 | 0.238 | ||||

| 3 | 0.2391 | 10.00 | 0.2500 | 0.2294 | 0.259 | ||||

| 2 | 0.2656 | 0.2576 | 0.284 | ||||||

| 1 | 0.2812 | 0.2893 | 0.300 | ||||||