Aluminum is a lightweight, silvery-white, soft, and malleable metal with many uses:

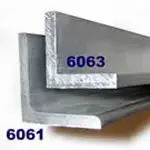

Aluminum Angle in 6061-T6 Structural has a rounded inside corner for increased strength. The 6063-T5...

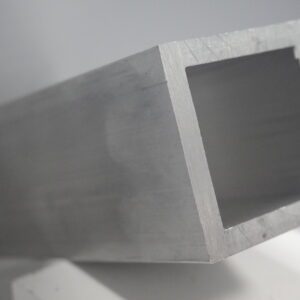

Aluminum 6063-T5 Square & Rectangular Tube is used in many fabrication projects where being lightweight,...

The aluminum channel is a structural metal component that is used in a variety of industrial...

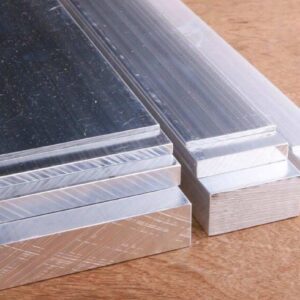

Aluminum Flat bar produced in 6061-T6 is the most versatile of the heat treatable alloys....

Aluminum Round Bar 6061-T6 is used in many fabrication projects. Being light weight and strong,...

An aluminum square bar is a square-shaped bar made from aluminum alloy. It is a versatile, lightweight,...

This category contains materials such as: Aluminum Sheet 6061-T6, Aluminum Sheet 5052-H32, in both bare,...

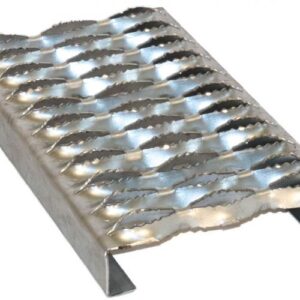

Aluminum Tread Bright (3003-H22) is a sheet product with a raised diamond pattern and a...

Aluminum Plate 6061-T651 Plate is one of the most versatile of all aluminum products. It...

“Aluminum expanded metal flat” refers to a sheet of aluminum that has been processed through...

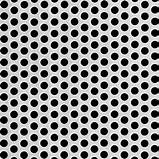

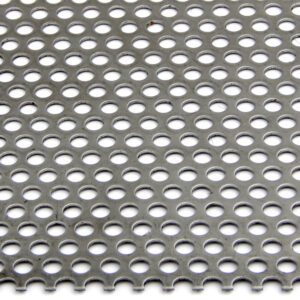

An aluminum perforated sheet metal is a sheet of aluminum that has been punched with...

Aluminum Cast Tooling Plate is a precision cast plate product. This fine-grain casting process and...

Aluminum Round Tube produced in 6061-T6 is probably the most widely used alloy due to...

Schedule 40 Aluminum 6061-T6 Pipe is also described as structural pipe. 6061-T6 pipe is used...

Metals4Uonline offers fabricated products such as Aluminum Tread Brite Angles

Plank grating is a type of safety grating used in various settings to provide secure...

Our Aluminum Economy Value Packs are pre-packaged in 4 foot (48″) lengths. Shipped straight to...

AFL611812

SHOP THIS ITEM $9.00 – $107.00Price range: $9.00 through $107.00 Select options This product has multiple variants. The options may be chosen on the product page

APE0631438

SHOP THIS ITEM $60.00 – $170.00Price range: $60.00 through $170.00 Select options This product has multiple variants. The options may be chosen on the product page

APE06338916

SHOP THIS ITEM $60.00 – $170.00Price range: $60.00 through $170.00 Select options This product has multiple variants. The options may be chosen on the product page

AFXM12051

SHOP THIS ITEM $33.00 – $87.00Price range: $33.00 through $87.00 Select options This product has multiple variants. The options may be chosen on the product page

AFXM34081

SHOP THIS ITEM $42.00 – $115.00Price range: $42.00 through $115.00 Select options This product has multiple variants. The options may be chosen on the product page

ART61250035

SHOP THIS ITEM $8.27 – $49.63Price range: $8.27 through $49.63 Select options This product has multiple variants. The options may be chosen on the product page

APG124.75

SHOP THIS ITEM $91.36 – $165.81Price range: $91.36 through $165.81 Select options This product has multiple variants. The options may be chosen on the product page

(1/4 Hard)

ASH52032

SHOP THIS ITEM $12.23 – $38.25Price range: $12.23 through $38.25 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)*(1/4 Hard)

ASH52032PVC

SHOP THIS ITEM $13.90 – $57.24Price range: $13.90 through $57.24 Select options This product has multiple variants. The options may be chosen on the product page

AANTB0322063

SHOP THIS ITEM $26.50 Add to cart

AANTB0322125

SHOP THIS ITEM $39.50 Add to cart

AANTB0322190

SHOP THIS ITEM $48.00 Add to cart

AANTB0333063

SHOP THIS ITEM $31.50 Add to cart

AANTB0333125

SHOP THIS ITEM $44.00 Add to cart

AANTB0333190

SHOP THIS ITEM $64.50 Add to cart

AAN631212116

SHOP THIS ITEM $8.00 – $109.00Price range: $8.00 through $109.00 Select options This product has multiple variants. The options may be chosen on the product page

commonly used on ambulances, fire trucks, trailers and toolboxes

ATB03025

SHOP THIS ITEM $21.45 – $85.80Price range: $21.45 through $85.80 Select options This product has multiple variants. The options may be chosen on the product page

commonly used on ambulances, fire trucks, trailers and toolboxes

ATB03063

SHOP THIS ITEM $18.01 – $106.12Price range: $18.01 through $106.12 Select options This product has multiple variants. The options may be chosen on the product page

AST631212062

SHOP THIS ITEM $8.03 – $55.00Price range: $8.03 through $55.00 Select options This product has multiple variants. The options may be chosen on the product page

commonly used on ambulances, fire trucks, trailers and toolboxes

ATB03125

SHOP THIS ITEM $27.22 – $216.85Price range: $27.22 through $216.85 Select options This product has multiple variants. The options may be chosen on the product page

commonly used on ambulances, fire trucks, trailers and toolboxes

ATB03188

SHOP THIS ITEM $32.75 – $282.97Price range: $32.75 through $282.97 Select options This product has multiple variants. The options may be chosen on the product page

AST63121125

SHOP THIS ITEM $3.60 – $19.70Price range: $3.60 through $19.70 Select options This product has multiple variants. The options may be chosen on the product page

AST633434062

SHOP THIS ITEM $7.67 – $87.85Price range: $7.67 through $87.85 Select options This product has multiple variants. The options may be chosen on the product page

AST633434125

SHOP THIS ITEM $29.17 – $301.01Price range: $29.17 through $301.01 Select options This product has multiple variants. The options may be chosen on the product page

AST6334112125

SHOP THIS ITEM $5.01 – $26.04Price range: $5.01 through $26.04 Select options This product has multiple variants. The options may be chosen on the product page

AST6311062

SHOP THIS ITEM $8.89 – $42.74Price range: $8.89 through $42.74 Select options This product has multiple variants. The options may be chosen on the product page

AST6311125

SHOP THIS ITEM $10.36 – $28.17Price range: $10.36 through $28.17 Select options This product has multiple variants. The options may be chosen on the product page

AST631112125

SHOP THIS ITEM $7.76 – $33.85Price range: $7.76 through $33.85 Select options This product has multiple variants. The options may be chosen on the product page

AST6312125

SHOP THIS ITEM $12.01 – $39.19Price range: $12.01 through $39.19 Select options This product has multiple variants. The options may be chosen on the product page

AST6313125

SHOP THIS ITEM $11.75 – $55.25Price range: $11.75 through $55.25 Select options This product has multiple variants. The options may be chosen on the product page

AST63114114062

SHOP THIS ITEM $4.44 – $22.62Price range: $4.44 through $22.62 Select options This product has multiple variants. The options may be chosen on the product page

AST63114114125

SHOP THIS ITEM $32.54 – $87.63Price range: $32.54 through $87.63 Select options This product has multiple variants. The options may be chosen on the product page

AST63112112062

SHOP THIS ITEM $3.93 – $19.57Price range: $3.93 through $19.57 Select options This product has multiple variants. The options may be chosen on the product page

AST63112112125

SHOP THIS ITEM $11.50 – $37.85Price range: $11.50 through $37.85 Select options This product has multiple variants. The options may be chosen on the product page

AST631122125

SHOP THIS ITEM $7.17 – $40.53Price range: $7.17 through $40.53 Select options This product has multiple variants. The options may be chosen on the product page

AST63134134125

SHOP THIS ITEM $13.00 – $43.50Price range: $13.00 through $43.50 Select options This product has multiple variants. The options may be chosen on the product page

AST631123125

SHOP THIS ITEM $16.40 – $59.52Price range: $16.40 through $59.52 Select options This product has multiple variants. The options may be chosen on the product page

AST631343125

SHOP THIS ITEM $16.51 – $61.06Price range: $16.51 through $61.06 Select options This product has multiple variants. The options may be chosen on the product page

AST631344125

SHOP THIS ITEM $12.02 – $65.13Price range: $12.02 through $65.13 Select options This product has multiple variants. The options may be chosen on the product page

AST6322125

SHOP THIS ITEM $10.35 – $45.30Price range: $10.35 through $45.30 Select options This product has multiple variants. The options may be chosen on the product page

AST6323125

SHOP THIS ITEM $17.67 – $66.04Price range: $17.67 through $66.04 Select options This product has multiple variants. The options may be chosen on the product page

AST6324125

SHOP THIS ITEM $16.00 – $69.77Price range: $16.00 through $69.77 Select options This product has multiple variants. The options may be chosen on the product page

AST6325125

SHOP THIS ITEM $16.18 – $81.06Price range: $16.18 through $81.06 Select options This product has multiple variants. The options may be chosen on the product page

AST6326125

SHOP THIS ITEM $22.00 – $95.00Price range: $22.00 through $95.00 Select options This product has multiple variants. The options may be chosen on the product page

AST63212212125

SHOP THIS ITEM $15.47 – $60.92Price range: $15.47 through $60.92 Select options This product has multiple variants. The options may be chosen on the product page

AST6333125

SHOP THIS ITEM $23.74 – $126.47Price range: $23.74 through $126.47 Select options This product has multiple variants. The options may be chosen on the product page

1/4" Aluminum Square 6061-T6

ASQ6114

SHOP THIS ITEM $7.86 – $10.57Price range: $7.86 through $10.57 Select options This product has multiple variants. The options may be chosen on the product page

ASQ6138

SHOP THIS ITEM $11.00 – $95.00Price range: $11.00 through $95.00 Select options This product has multiple variants. The options may be chosen on the product page

AST6344125

SHOP THIS ITEM $25.94 – $133.07Price range: $25.94 through $133.07 Select options This product has multiple variants. The options may be chosen on the product page

ASQ6112

SHOP THIS ITEM $7.50 – $38.00Price range: $7.50 through $38.00 Select options This product has multiple variants. The options may be chosen on the product page

ASQ6158

SHOP THIS ITEM $9.92 – $25.52Price range: $9.92 through $25.52 Select options This product has multiple variants. The options may be chosen on the product page

ASQ6134

SHOP THIS ITEM $8.00 – $33.00Price range: $8.00 through $33.00 Select options This product has multiple variants. The options may be chosen on the product page

ASQ611

SHOP THIS ITEM $13.00 – $56.05Price range: $13.00 through $56.05 Select options This product has multiple variants. The options may be chosen on the product page

ASQ61112

SHOP THIS ITEM $27.00 – $106.06Price range: $27.00 through $106.06 Select options This product has multiple variants. The options may be chosen on the product page

ASQ612

SHOP THIS ITEM $41.68 – $213.59Price range: $41.68 through $213.59 Select options This product has multiple variants. The options may be chosen on the product page

ASQ613

SHOP THIS ITEM $80.00 – $403.14Price range: $80.00 through $403.14 Select options This product has multiple variants. The options may be chosen on the product page

ART61250058

SHOP THIS ITEM $3.89 – $23.36Price range: $3.89 through $23.36 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)*(1/4 Hard)

ASH61040PVC

SHOP THIS ITEM $20.14 – $97.55Price range: $20.14 through $97.55 Select options This product has multiple variants. The options may be chosen on the product page

ART61375035

SHOP THIS ITEM $4.66 – $27.98Price range: $4.66 through $27.98 Select options This product has multiple variants. The options may be chosen on the product page

ASQ614

SHOP THIS ITEM $123.94 – $718.64Price range: $123.94 through $718.64 Select options This product has multiple variants. The options may be chosen on the product page

ART61375058

SHOP THIS ITEM $8.03 – $48.18Price range: $8.03 through $48.18 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)*(1/4 Hard)

ASH61050PVC

SHOP THIS ITEM $15.04 – $70.47Price range: $15.04 through $70.47 Select options This product has multiple variants. The options may be chosen on the product page

ART61500035

SHOP THIS ITEM $9.99 – $59.93Price range: $9.99 through $59.93 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)*(1/4 Hard)

ASH61063PVC

SHOP THIS ITEM $16.36 – $86.38Price range: $16.36 through $86.38 Select options This product has multiple variants. The options may be chosen on the product page

ART61500058

SHOP THIS ITEM $9.92 – $59.53Price range: $9.92 through $59.53 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)*(1/4 Hard)

ASH61090PVC

SHOP THIS ITEM $22.80 – $163.61Price range: $22.80 through $163.61 Select options This product has multiple variants. The options may be chosen on the product page

ART61500065

SHOP THIS ITEM $13.28 – $79.68Price range: $13.28 through $79.68 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)*(1/4 Hard)

ASH61125PVC

SHOP THIS ITEM $28.09 – $227.10Price range: $28.09 through $227.10 Select options This product has multiple variants. The options may be chosen on the product page

ART61625058

SHOP THIS ITEM $10.34 – $62.04Price range: $10.34 through $62.04 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)*(1/4 Hard)

ASH61190PVC

SHOP THIS ITEM $29.11 – $239.30Price range: $29.11 through $239.30 Select options This product has multiple variants. The options may be chosen on the product page

ART61625035

SHOP THIS ITEM $9.64 – $57.82Price range: $9.64 through $57.82 Select options This product has multiple variants. The options may be chosen on the product page

(1/4 Hard)

ASH52040

SHOP THIS ITEM $13.00 – $47.00Price range: $13.00 through $47.00 Select options This product has multiple variants. The options may be chosen on the product page

ART61750035

SHOP THIS ITEM $11.74 – $70.44Price range: $11.74 through $70.44 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)*(1/4 Hard)

ASH52040PVC

SHOP THIS ITEM $14.00 – $45.00Price range: $14.00 through $45.00 Select options This product has multiple variants. The options may be chosen on the product page

ART61750058

SHOP THIS ITEM $9.90 – $59.40Price range: $9.90 through $59.40 Select options This product has multiple variants. The options may be chosen on the product page

(1/4 Hard)

ASH52063

SHOP THIS ITEM $16.14 – $83.66Price range: $16.14 through $83.66 Select options This product has multiple variants. The options may be chosen on the product page

ART61875058

SHOP THIS ITEM $7.00 – $42.00Price range: $7.00 through $42.00 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)*(1/4 Hard)

ASH52063PVC

SHOP THIS ITEM $14.40 – $62.79Price range: $14.40 through $62.79 Select options This product has multiple variants. The options may be chosen on the product page

ART61875035

SHOP THIS ITEM $11.74 – $70.44Price range: $11.74 through $70.44 Select options This product has multiple variants. The options may be chosen on the product page

(1/4 Hard)

ASH52090

SHOP THIS ITEM $16.20 – $97.33Price range: $16.20 through $97.33 Select options This product has multiple variants. The options may be chosen on the product page

ART611000035

SHOP THIS ITEM $13.94 – $78.64Price range: $13.94 through $78.64 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)*(1/4 Hard)

ASH52090PVC

SHOP THIS ITEM $16.20 – $97.33Price range: $16.20 through $97.33 Select options This product has multiple variants. The options may be chosen on the product page

ART611000058

SHOP THIS ITEM $13.13 – $78.80Price range: $13.13 through $78.80 Select options This product has multiple variants. The options may be chosen on the product page

(1/4 Hard)

ASH52125

SHOP THIS ITEM $22.21 – $166.00Price range: $22.21 through $166.00 Select options This product has multiple variants. The options may be chosen on the product page

ART611000125

SHOP THIS ITEM $2.99 – $17.95Price range: $2.99 through $17.95 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)*(1/4 Hard)

ASH52125PVC

SHOP THIS ITEM $35.00 – $180.40Price range: $35.00 through $180.40 Select options This product has multiple variants. The options may be chosen on the product page

ART611125058

SHOP THIS ITEM $11.99 – $71.94Price range: $11.99 through $71.94 Select options This product has multiple variants. The options may be chosen on the product page

(1/4 Hard)

ASH52190

SHOP THIS ITEM $29.91 – $248.51Price range: $29.91 through $248.51 Select options This product has multiple variants. The options may be chosen on the product page

ART611250058

SHOP THIS ITEM $12.69 – $76.16Price range: $12.69 through $76.16 Select options This product has multiple variants. The options may be chosen on the product page

(PVC Coated)*(1/4 Hard)

ASH52190PVC

SHOP THIS ITEM $23.21 – $168.48Price range: $23.21 through $168.48 Select options This product has multiple variants. The options may be chosen on the product page

ART611250125

SHOP THIS ITEM $7.23 – $27.88Price range: $7.23 through $27.88 Select options This product has multiple variants. The options may be chosen on the product page

APL52250

SHOP THIS ITEM $62.30 – $391.16Price range: $62.30 through $391.16 Select options This product has multiple variants. The options may be chosen on the product page

ART611375058

SHOP THIS ITEM $13.82 – $82.92Price range: $13.82 through $82.92 Select options This product has multiple variants. The options may be chosen on the product page

APL52375

SHOP THIS ITEM $51.66 – $533.09Price range: $51.66 through $533.09 Select options This product has multiple variants. The options may be chosen on the product page

ART611500058

SHOP THIS ITEM $14.36 – $86.16Price range: $14.36 through $86.16 Select options This product has multiple variants. The options may be chosen on the product page

ART611500125

SHOP THIS ITEM $6.45 – $38.68Price range: $6.45 through $38.68 Select options This product has multiple variants. The options may be chosen on the product pageThe word Aluminum, is derived from the old French word alum, which in turn comes from the Latin word alumen that means bitter salt. Aluminum, which is a metallic element, has a very low density and does not corrode easily. Aluminum salts have been in use since the time of the Ancient Romans and Greeks. However, the metal itself was first produced, albeit not in its purest form, for the first time in the year 1825 by H. C. Oersted, a Danish chemist and physicist. The credit for isolating the metal, however, goes to Frederich Wohler, a German chemist, who did so in 1827.

Aluminum is not available in pure form in nature and has to be extracted from other compounds. Today, the metal is extracted mainly from an ore called Bauxite, which contains, in addition to aluminum oxide (or alumina, as it is also known), compounds like silica, titanium dioxide and a number of different iron oxides. The process of extraction involves two main steps. The first step is the Bayer process and the second step is the Hall-Heroult process.

In the year 1887, Carl Joseph Bayer invented the Bayer process. In this procedure, aluminum oxide is extracted from bauxite. The ore is washed with sodium hydroxide at a high pressure and temperature. The result is that the aluminum oxide present in the ore gets converted to sodium aluminate, which is soluble. The sodium aluminate, when dissolved in alkaline water, is converted to aluminum hydroxide. This compound is then calcined – in other words, aluminum hydroxide is heated to a very high temperature, of around 980 degrees Celsius – resulting in decomposition of the compound into aluminum oxide.

The Hall-Heroult process is named after C. M. Hall, an American Chemist, and Paul Herault, a French scientist. The two of them invented the process independently in the year 1886. It is an electrolytic process used to convert aluminum oxide to pure aluminum. The procedure is conducted in the following way: the aluminum oxide (obtained from Bayer process, for example) is dissolved in molten cryolite along with some aluminum fluoride. Then, a low voltage direct current is passed through this molten mixture to electrolyze it. A cell is built specifically for this process. The result of the electrolysis is the deposition of pure aluminum on the cathode of the cell, from where it is collected periodically.

* Prices subject to change without notice due to the Metals Market fluctuations.

* All ‘value length’ and ‘value pack’ item measurements are subject to a “mill tolerance”. A product may be produced several thousandths of an inch, either over or under the stated thickness, and still be within “mill tolerance”. This does NOT apply to Cut To Size items. Those will be +.125″, -0.00″ tolerances.

|

Pipe Size* |

O.D.

(in.) |

Schedule (10, 40, 80)

Wall Thickness (in.)** |

|||||

|---|---|---|---|---|---|---|---|

| Sch.10 | Sch.40 | Sch.80 | |||||

| Wall (in) | I.D. (in) | Wall (in) | I.D. (in) | Wall (in) | I.D. (in) | ||

| 1/8" | 0.41 od | 0.049 in | 0.312 id | 0.07 in | 0.269 id | ||

|

Weight (lbs/ft.) |

Steel | 0.183 lbs/ft | 0.247 lbs/ft | ||||

| Stainless | |||||||

| Aluminum | |||||||

| 1/4" | 0.54 od | 0.065 in | 0.410 id | 0.090 in | 0.364 id | 0.119 in | 0.302 id |

|

Weight (lbs/ft.) |

Steel | 0.333 lbs/ft | 0.429 lbs/ft | 0.535 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.147 lbs/ft | ||||||

| 3/8" | 0.675 od | 0.065 in | 0.545 id | 0.091 in | 0.493 id | 0.126 in | 0.423 id |

|

Weight (lbs/ft.) |

Steel | 0.420 lbs/ft | 0.570 lbs/ft | 0.740 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.196 lbs/ft | ||||||

| 1/2" | 0.840 od | 0.083 in | 0.674 id | 0.109 in | 0.622 id | 0.147 in | 0.546 id |

|

Weight (lbs/ft.) |

Steel | 0.670 lbs/ft | 0.850 lbs/ft | 1.090 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.294 lbs/ft | 0.384 lbs/ft | |||||

| 3/4" | 1.050 od | 0.083 in | 0.884 id | 0.113 in | 0.824 id | 0.154 in | 0.742 id |

|

Weight (lbs/ft.) |

Steel | 0.86 lbs/ft | 1.13 lbs/ft | 1.48 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.391 | 0.520 | |||||

| 1" | 1.315 od | 0.109 in | 1.097 id | 0.133 in | 1.049 id | 0.179 in | 0.957 id |

|

Weight (lbs/ft.) |

Steel | 1.41 lbs/ft | 1.68 lbs/ft | 2.17 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.481 lbs/ft | 0.581 lbs/ft | 0.781 lbs/ft | ||||

| 1-1/4" | 1.66 od | 0.109 in | 1.442 id | 0.140 in | 1.380 id | 0.191 in | 1.278 id |

|

Weight (lbs/ft.) |

Steel | 1.81 lbs/ft | 2.27 lbs/ft | 3.00 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.618 lbs/ft | 0.785 lbs/ft | 1.040 lbs/ft | ||||

| 1-1/2" | 1.90 od | 0.109 in | 1.682 id | 0.145 in | 1.610 id | 0.200 in | 1.500 id |

|

Weight (lbs/ft.) |

Steel | 2.09 lbs/ft | 2.72 lbs/ft | 3.63 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.714 lbs/ft | 0.939 lbs/ft | 1.260 lbs/ft | ||||

| 2" | 2.375 od | 0.109 in | 2.157 id | 0.154 in | 2.067 id | 0.218 in | 1.939 id |

|

Weight (lbs/ft.) |

Steel | 2.64 lbs/ft | 3.66 lbs/ft | 5.03 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 0.903 lbs/ft | 1.260 lbs/ft | 1.740 lbs/ft | ||||

| 2-1/2" | 2.875 od | 0.120 in | 2.635 id | 0.203 in | 2.469 id | 0.276 in | 2.323 id |

|

Weight (lbs/ft.) |

Steel | 3.53 lbs/ft | 5.80 lbs/ft | 7.67 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 1.209 lbs/ft | 2.000 lbs/ft | |||||

| 3" | 3.50 od | 0.120 in | 3.26 id | 0.216 in | 3.068 id | 0.30 in | 2.90 id |

|

Weight (lbs/ft.) |

Steel | 4.34 lbs/ft | 7.58 lbs/ft | 10.26 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 1.483 lbs/ft | 2.620 lbs/ft | 3.55 lbs/ft | ||||

| 3-1/2" | 4.00 od | 0.120 in | 3.76 id | 0.226 in | 3.550 id | 0.318 in | 3.360 id |

|

Weight (lbs/ft.) |

Steel | 4.98 lbs/ft | 9.12 lbs/ft | 12.52 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 3.150 lbs/ft | 4.33 lbs/ft | |||||

| 4" | 4.50 od | 0.120 in | 4.26 id | 0.237 in | 4.026 id | 0.337 in | 3.826 id |

|

Weight (lbs/ft.) |

Steel | 5.62 lbs/ft | 10.80 lbs/ft | 15.00 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 1.922 lbs/ft | 3.730 lbs/ft | 5.180 lbs/ft | ||||

| 5" | 5.563 od | 0.134 in | 5.295 id | 0.258 in | 5.047 id | 0.375 in | 4.813 id |

|

Weight (lbs/ft.) |

Steel | 7.78 lbs/ft | 14.63 lbs/ft | 20.80 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 2.660 lbs/ft | 5.050 lbs/ft | 7.190 lbs/ft | ||||

| 6" | 6.625 od | 0.134 in | 6.357 id | 0.280 in | 6.065 id | 0.432 in | 5.761 id |

|

Weight (lbs/ft.) |

Steel | 9.30 lbs/ft | 18.99 lbs/ft | 28.60 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 3.181 lbs/ft | 6.560 lbs/ft | 9.880 lbs/ft | ||||

| 8" | 8.625 od | 0.148 in | 8.329 id | 0.322 in | 7.981 id | 0.500 in | 7.625 id |

|

Weight (lbs/ft.) |

Steel | 13.41 lbs/ft | 28.58 lbs/ft | 43.43 lbs/ft | |||

| Stainless | |||||||

| Aluminum | 9.88 lbs/ft | 15.010 lbs/ft | |||||

|

*Nominal sizes apply - Pipe Size is the generic Industry Size Standard for reference only **Tolerances may vary slightly from each manufacturer |

|||||||

| Ga# | Sheet Steel | Galvanized Steel | Stainless Steel | Aluminum | Strip & Tubing | ||||

|---|---|---|---|---|---|---|---|---|---|

|

Ga (in.) |

Wgt (lb/ft2) |

Ga (in.) |

Wgt (lb/ft2) |

Ga (in.) |

Wgt (lb/ft2) |

Ga (in.) |

Wgt (lb/ft2) |

Ga (in.) |

|

| 38 | 0.0060 | 0.0062 | 0.0040 | ||||||

| 37 | 0.0064 | 0.0066 | 0.0045 | ||||||

| 36 | 0.0067 | 0.0070 | 0.0050 | 0.004 | |||||

| 35 | 0.0075 | 0.0078 | 0.0056 | 0.005 | |||||

| 34 | 0.0082 | 0.0086 | 0.0063 | 0.007 | |||||

| 33 | 0.0090 | 0.0094 | 0.0071 | 0.008 | |||||

| 32 | 0.0097 | 0.0102 | 0.0080 | 0.009 | |||||

| 31 | 0.0105 | 0.0109 | 0.0089 | 0.010 | |||||

| 30 | 0.0120 | 0.500 | 0.016 | 0.656 | 0.0125 | 0.0100 | 0.141 | 0.012 | |

| 29 | 0.0135 | 0.563 | 0.017 | 0.719 | 0.0141 | 0.0113 | 0.160 | 0.013 | |

| 28 | 0.0149 | 0.625 | 0.019 | 0.781 | 0.0156 | 0.0126 | 0.178 | 0.014 | |

| 27 | 0.0164 | 0.688 | 0.020 | 0.844 | 0.0172 | 0.0142 | 0.200 | 0.016 | |

| 26 | 0.0179 | 0.750 | 0.022 | 0.906 | 0.0187 | 0.756 | 0.0159 | 0.224 | 0.018 |

| 25 | 0.0209 | 0.875 | 0.025 | 1.031 | 0.0219 | 0.0179 | 0.253 | 0.020 | |

| 24 | 0.0239 | 1.000 | 0.028 | 1.156 | 0.0250 | 1.008 | 0.0201 | 0.284 | 0.022 |

| 23 | 0.0269 | 1.125 | 0.031 | 1.281 | 0.0281 | 0.0226 | 0.319 | 0.025 | |

| 22 | 0.0299 | 1.250 | 0.034 | 1.406 | 0.0312 | 1.26 | 0.0253 | 0.357 | 0.028 |

| 21 | 0.0329 | 1.375 | 0.037 | 1.531 | 0.0344 | 0.0285 | 0.402 | 0.032 | |

| 20 | 0.0359 | 1.500 | 0.040 | 1.656 | 0.0375 | 1.512 | 0.0320 | 0.452 | 0.035 |

| 19 | 0.0418 | 1.750 | 0.046 | 1.906 | 0.0437 | 0.0359 | 0.507 | 0.042 | |

| 18 | 0.0478 | 2.000 | 0.052 | 2.156 | 0.0500 | 2.016 | 0.0403 | 0.569 | 0.049 |

| 17 | 0.0538 | 2.250 | 0.058 | 2.406 | 0.0562 | 0.0453 | 0.639 | 0.058 | |

| 16 | 0.0598 | 2.500 | 0.064 | 2.656 | 0.0625 | 2.52 | 0.0508 | 0.717 | 0.065 |

| 15 | 0.0673 | 2.813 | 0.071 | 2.969 | 0.0703 | 0.0571 | 0.806 | 0.072 | |

| 14 | 0.0747 | 3.125 | 0.079 | 3.281 | 0.0781 | 3.15 | 0.0641 | 0.905 | 0.083 |

| 13 | 0.0897 | 3.750 | 0.093 | 3.906 | 0.0937 | 0.0720 | 1.016 | 0.095 | |

| 12 | 0.1046 | 4.375 | 0.108 | 4.531 | 0.1094 | 4.41 | 0.0808 | 1.140 | 0.109 |

| 11 | 0.1196 | 5.000 | 0.123 | 5.156 | 0.1250 | 5.04 | 0.0907 | 1.280 | 0.120 |

| 10 | 0.1345 | 5.625 | 0.138 | 5.781 | 0.1406 | 5.67 | 0.1019 | 1.438 | 0.134 |

| 9 | 0.1495 | 6.250 | 0.153 | 6.406 | 0.1562 | 0.1144 | 1.614 | 0.148 | |

| 8 | 0.1644 | 6.875 | 0.168 | 7.031 | 0.1719 | 6.93 | 0.1285 | 1.813 | 0.165 |

| 7 | 0.1793 | 7.500 | 0.1875 | 7.871 | 0.1443 | 2.036 | 0.180 | ||

| 6 | 0.1943 | 8.125 | 0.2031 | 0.1620 | 2.286 | 0.203 | |||

| 5 | 0.2092 | 8.750 | 0.2187 | 0.1819 | 0.220 | ||||

| 4 | 0.2242 | 9.375 | 0.2344 | 0.2043 | 0.238 | ||||

| 3 | 0.2391 | 10.00 | 0.2500 | 0.2294 | 0.259 | ||||

| 2 | 0.2656 | 0.2576 | 0.284 | ||||||

| 1 | 0.2812 | 0.2893 | 0.300 | ||||||