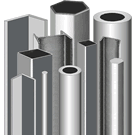

Aluminum

Aluminum, being strong and light weight with excellent corrosion resistance make this silver/gray material the second most used metal. Aluminum is easily machined, fabricated and welded by many common methods. The most common aluminum alloys are 6061 and 6063, and comes in all shapes and sizes.

History of Aluminum

The word Aluminum, is derived from the old French word alum, which in turn comes from the Latin word alumen that means bitter salt. Aluminum, which is a metallic element, has a very low density and does not corrode easily. Aluminum salts have been in use since the time of the Ancient Romans and Greeks. However, the metal itself was first produced, albeit not in its purest form, for the first time in the year 1825 by H. C. Oersted, a Danish chemist and physicist. The credit for isolating the metal, however, goes to Frederich Wohler, a German chemist, who did so in 1827.

Aluminum Production Process

Aluminum is not available in pure form in nature and has to be extracted from other compounds. Today, the metal is extracted mainly from an ore called Bauxite, which contains, in addition to aluminum oxide (or alumina, as it is also known), compounds like silica, titanium dioxide and a number of different iron oxides. The process of extraction involves two main steps. The first step is the Bayer process and the second step is the Hall-Heroult process.

In the year 1887, Carl Joseph Bayer invented the Bayer process. In this procedure, aluminum oxide is extracted from bauxite. The ore is washed with sodium hydroxide at a high pressure and temperature. The result is that the aluminum oxide present in the ore gets converted to sodium aluminate, which is soluble. The sodium aluminate, when dissolved in alkaline water, is converted to aluminum hydroxide. This compound is then calcined – in other words, aluminum hydroxide is heated to a very high temperature, of around 980 degrees Celsius – resulting in decomposition of the compound into aluminum oxide.

The Hall-Heroult process is named after C. M. Hall, an American Chemist, and Paul Herault, a French scientist. The two of them invented the process independently in the year 1886. It is an electrolytic process used to convert aluminum oxide to pure aluminum. The procedure is conducted in the following way: the aluminum oxide (obtained from Bayer process, for example) is dissolved in molten cryolite along with some aluminum fluoride. Then, a low voltage direct current is passed through this molten mixture to electrolyze it. A cell is built specifically for this process. The result of the electrolysis is the deposition of pure aluminum on the cathode of the cell, from where it is collected periodically.

+1 (214) 231-1434

*Prices subject to change without notice due to the Metals Market fluctuations.

* All 'value length' and 'value pack' item measurements are subject to a "mill tolerance". A product may be produced several thousandths of an inch, either over or under the stated thickness, and still be within "mill tolerance". This does NOT apply to Cut To Size items. Those will be +.125", -0.00" tolerances.